- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

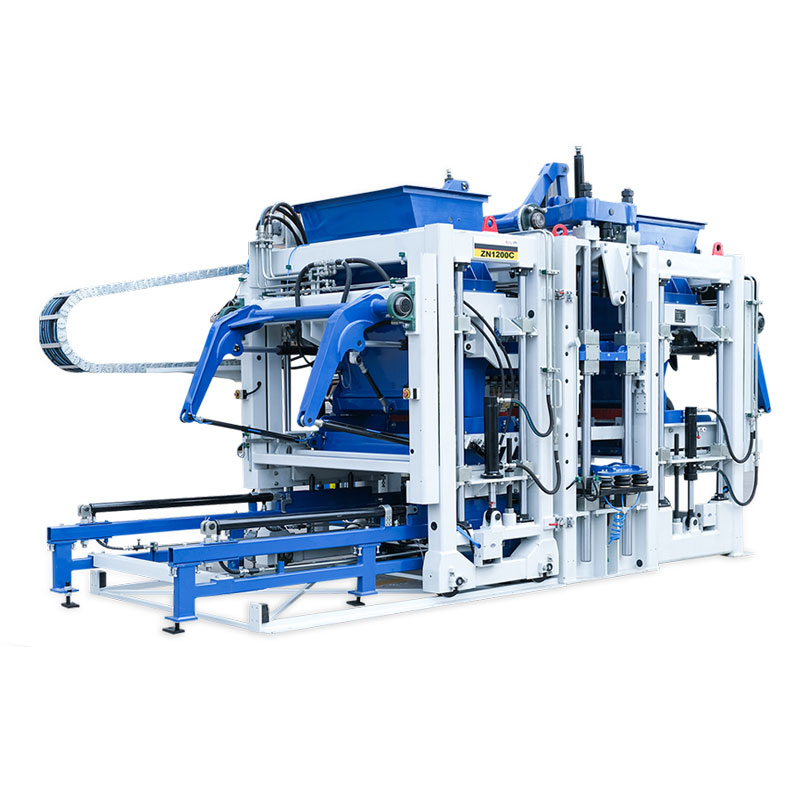

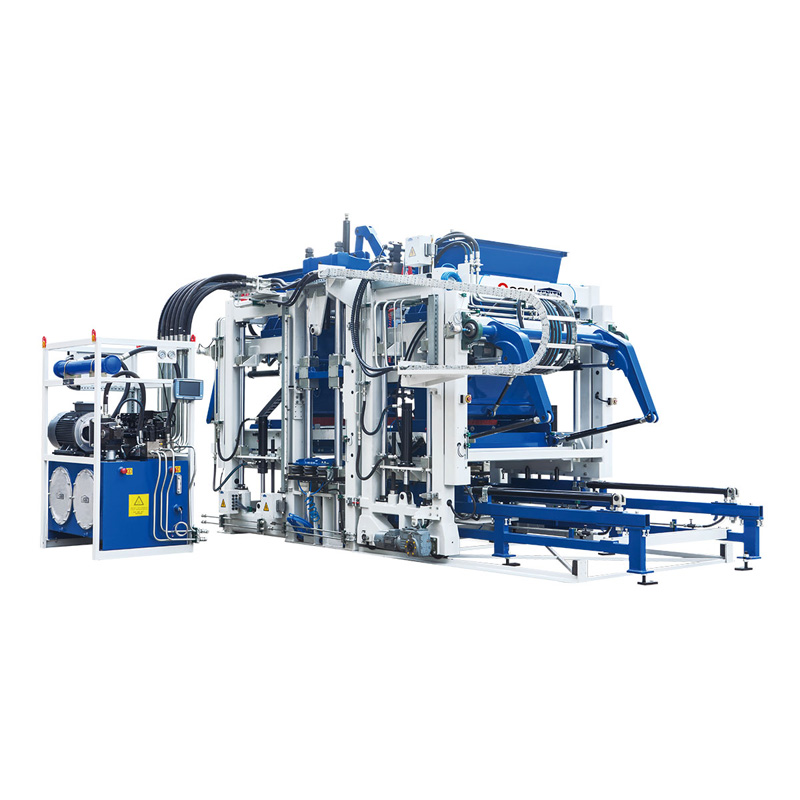

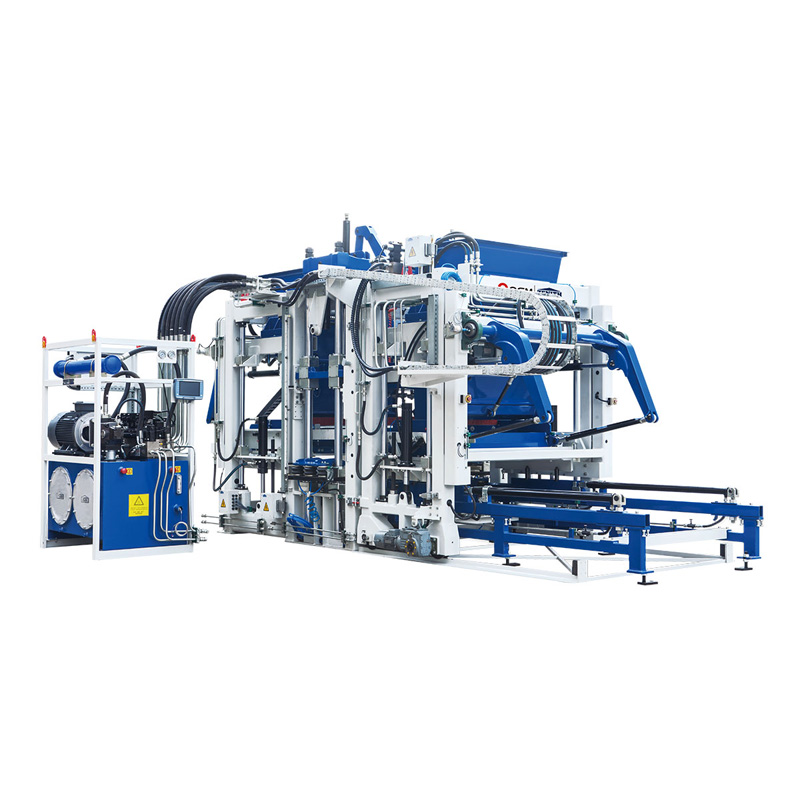

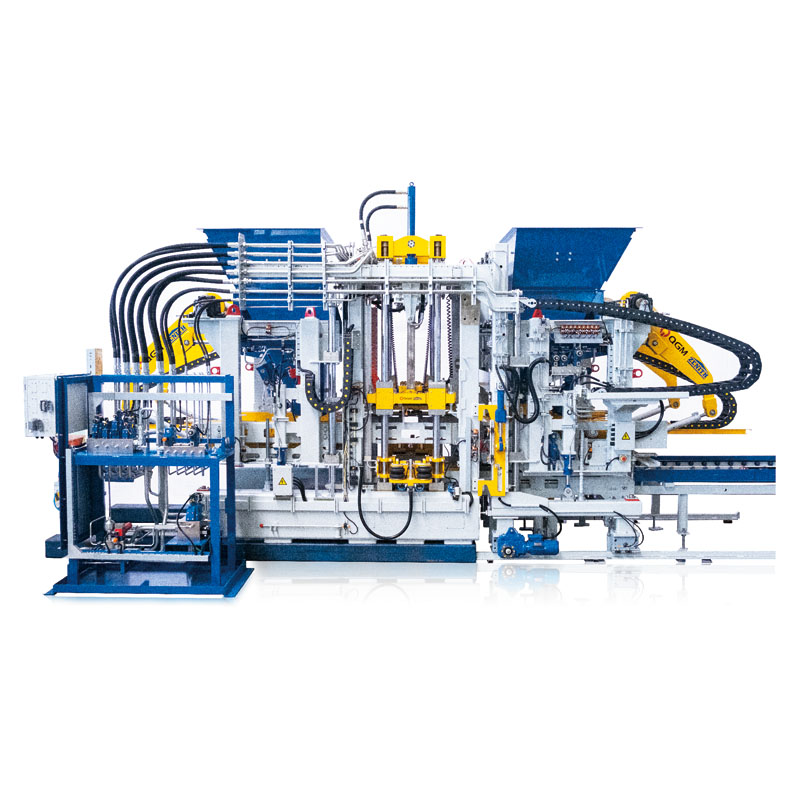

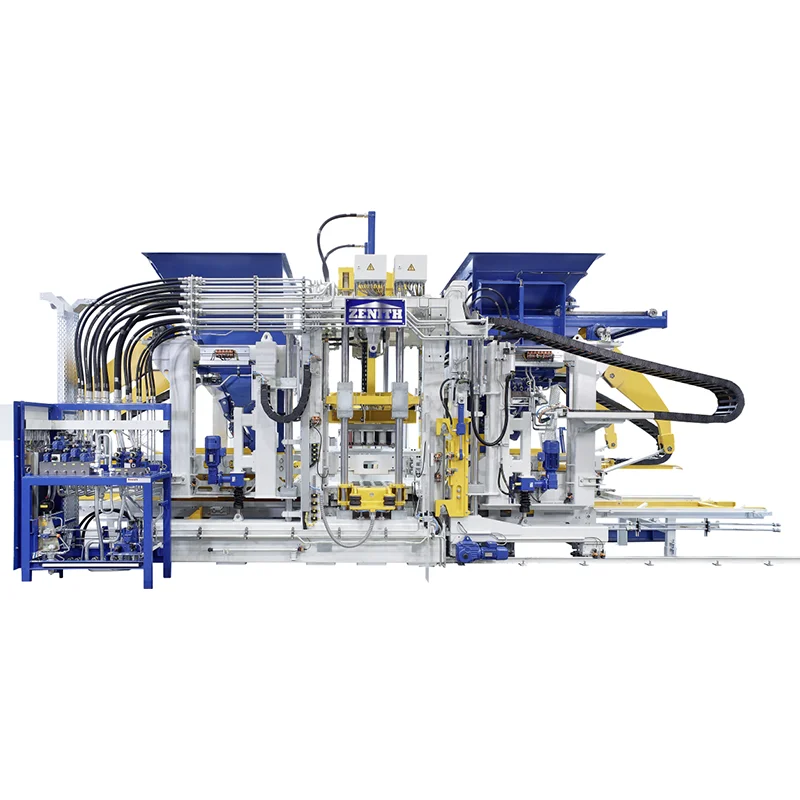

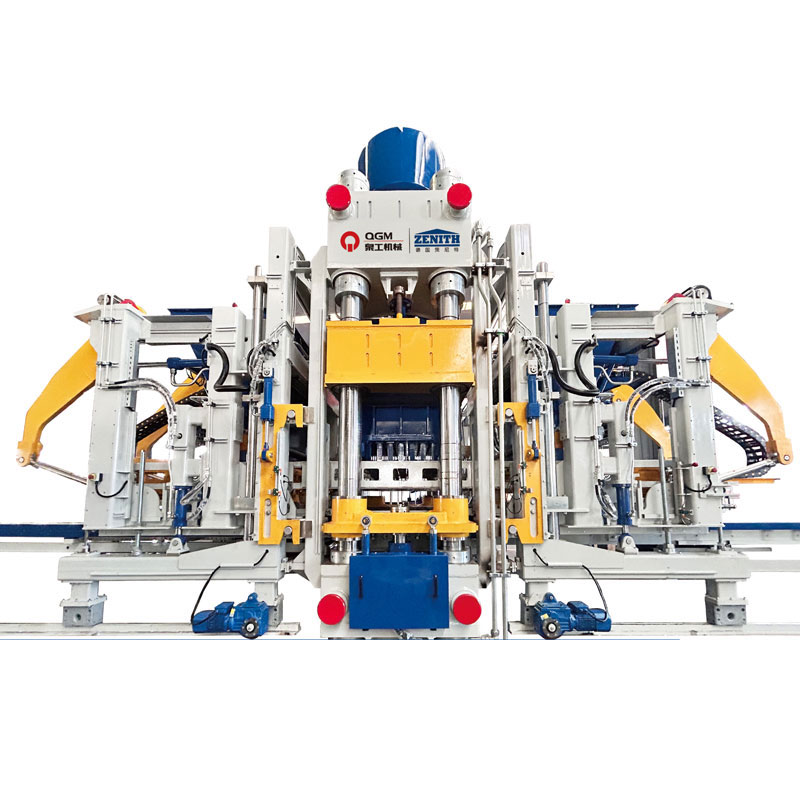

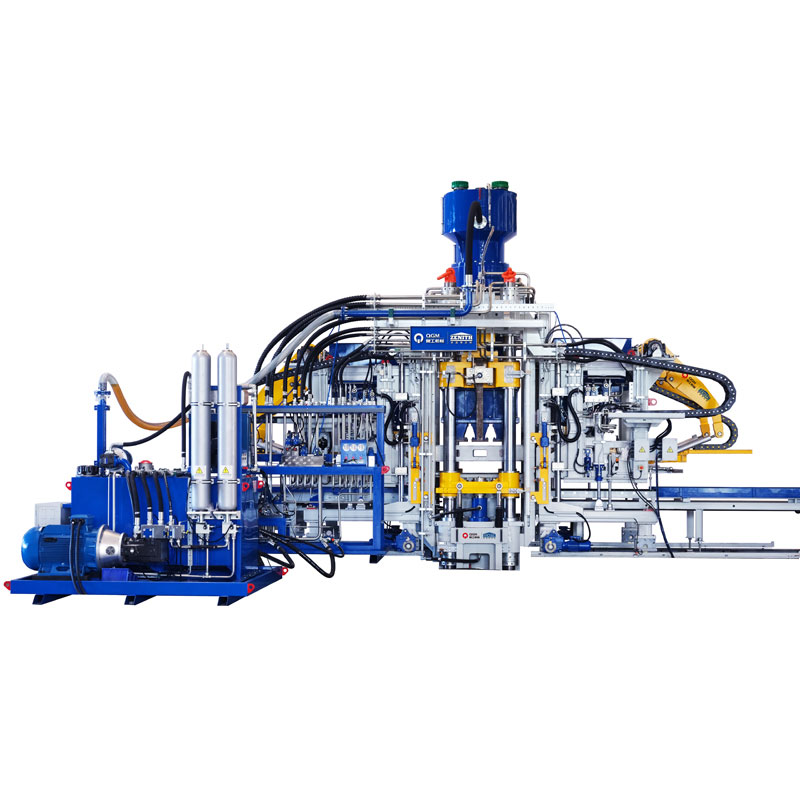

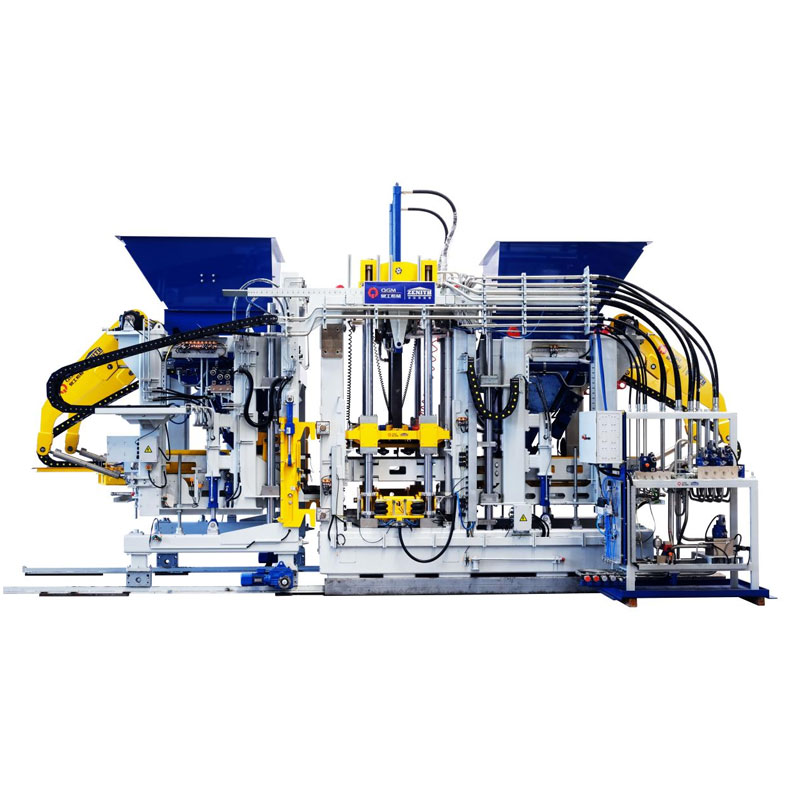

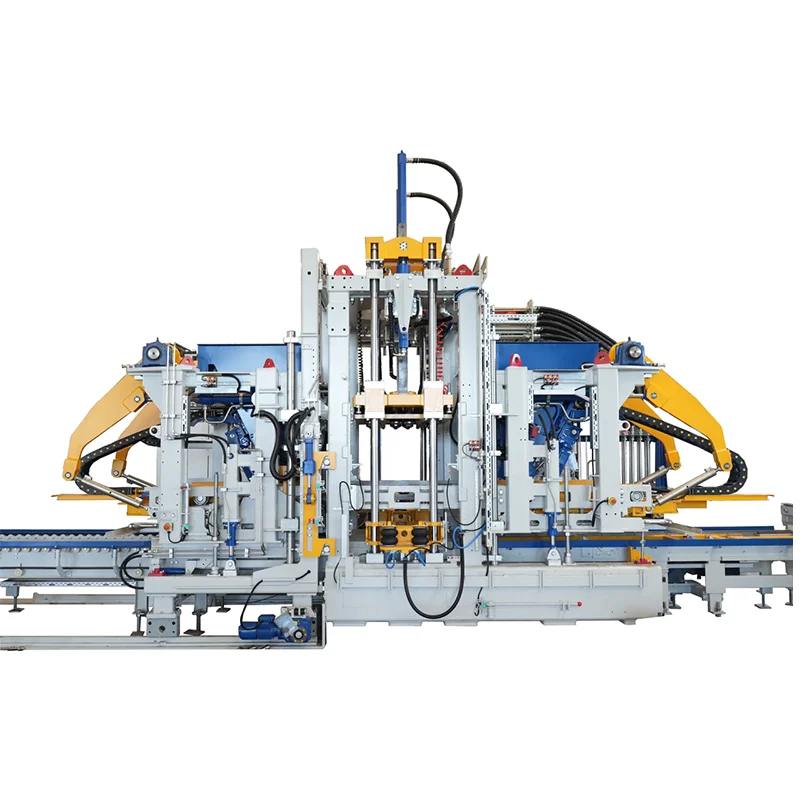

Zenith “Ultra-Dynamic” Four-Axis Servo Vibration

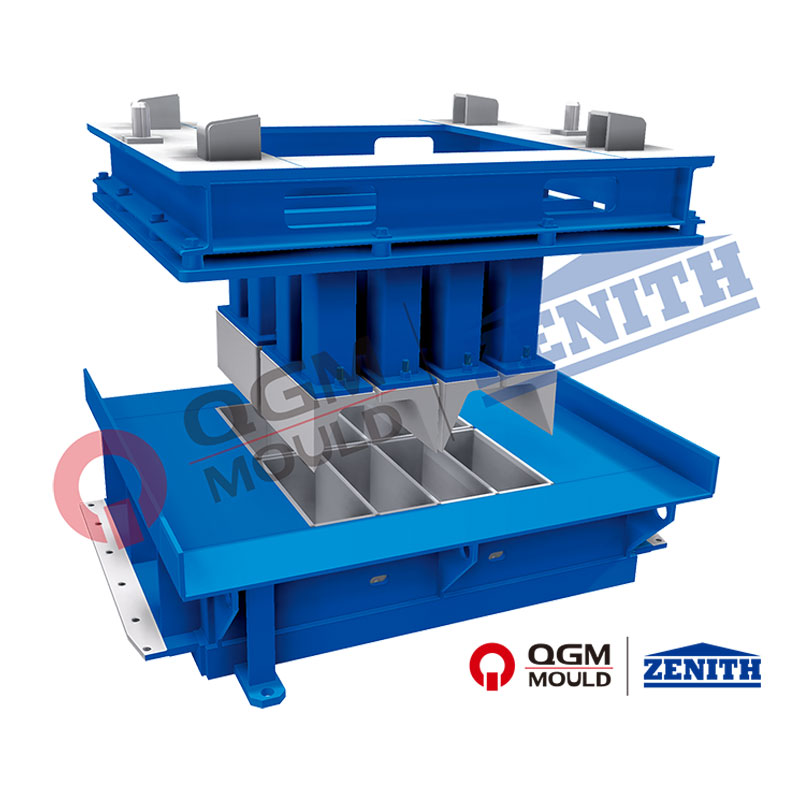

Zenith “Ultra-Dynamic” Four-Axis Servo Vibration Automatic Quick Mold Change System

Automatic Quick Mold Change System Suspended Feeding System

Suspended Feeding System Hydraulic Reciprocating Arch-Breaking Base Feeder

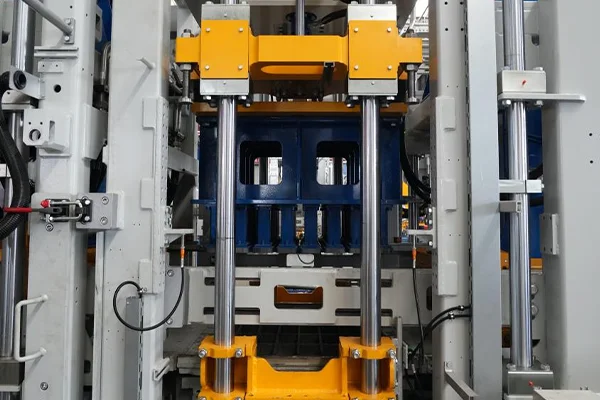

Hydraulic Reciprocating Arch-Breaking Base Feeder  Modular Main Frame

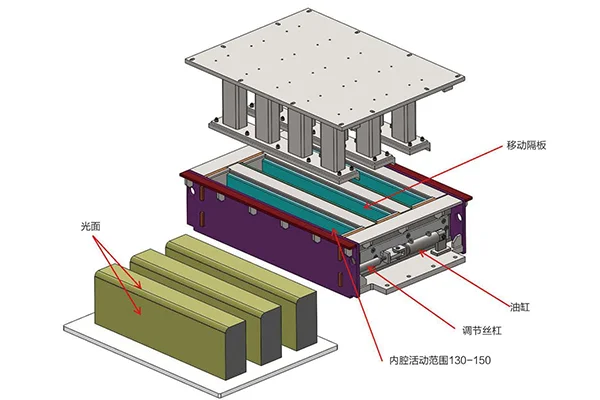

Modular Main Frame Hydraulic Automatic Locking Function for the Face Mix Unit

Hydraulic Automatic Locking Function for the Face Mix Unit Press Head Locking Device

Press Head Locking Device Electric Screw Lift Adjustment

Electric Screw Lift Adjustment Fully Integrated Control System

Fully Integrated Control System Extensive Expandability

Extensive Expandability Quangong Intelligent Equipment Cloud Service Platform

Quangong Intelligent Equipment Cloud Service Platform