- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

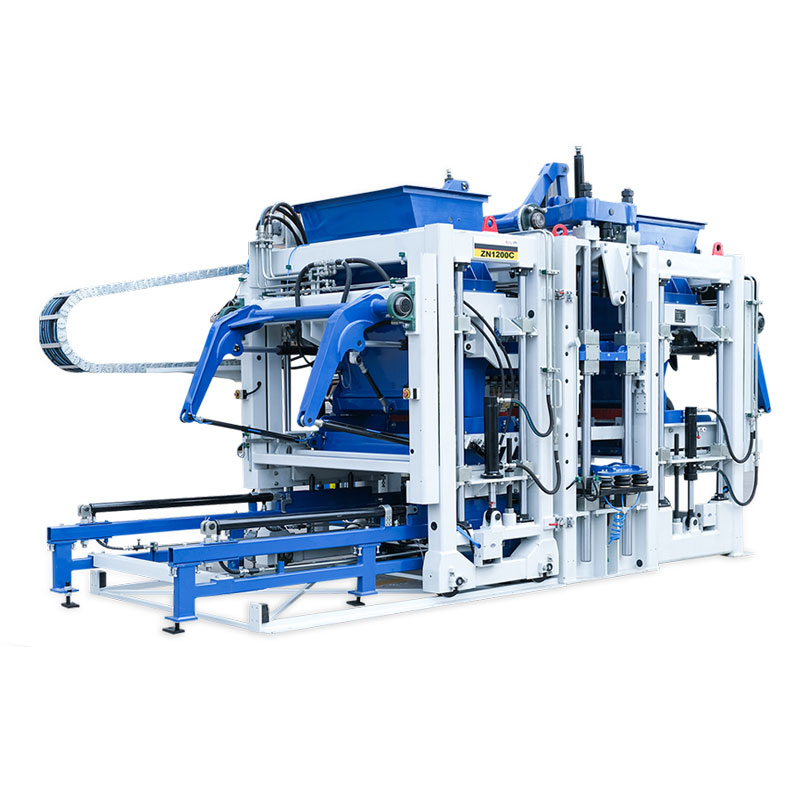

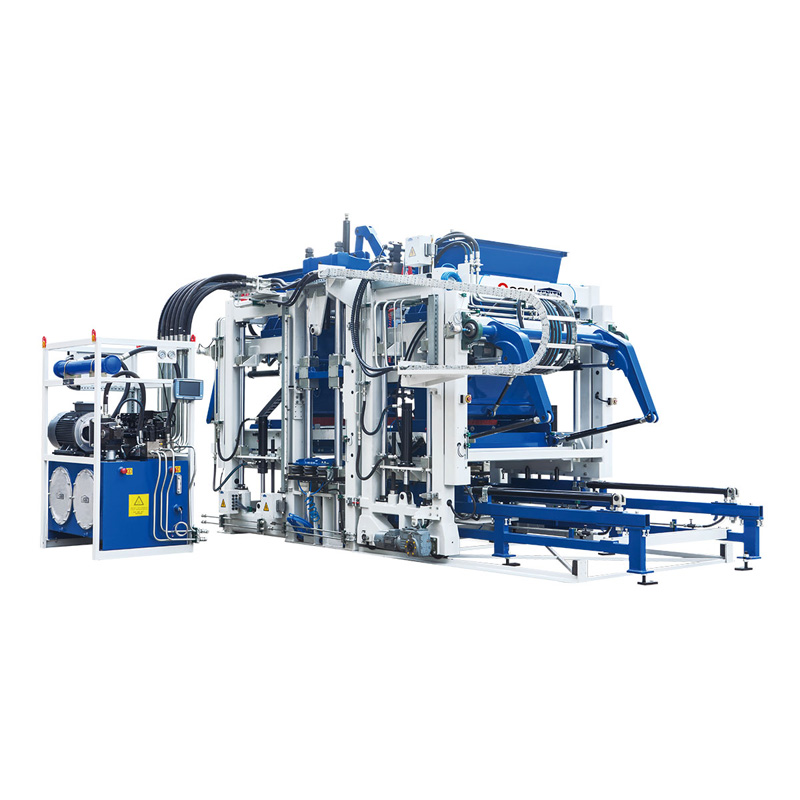

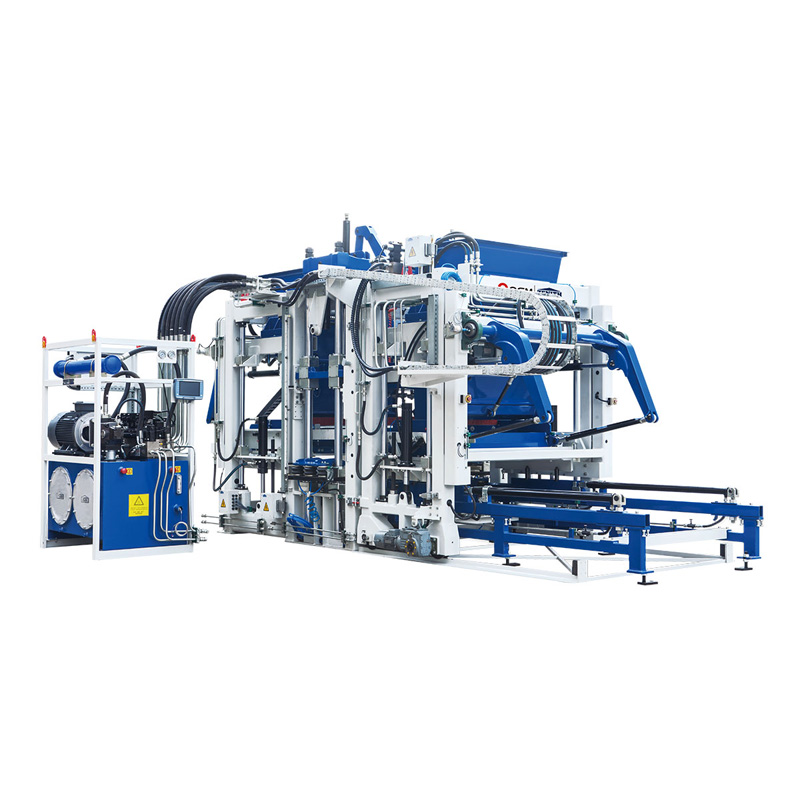

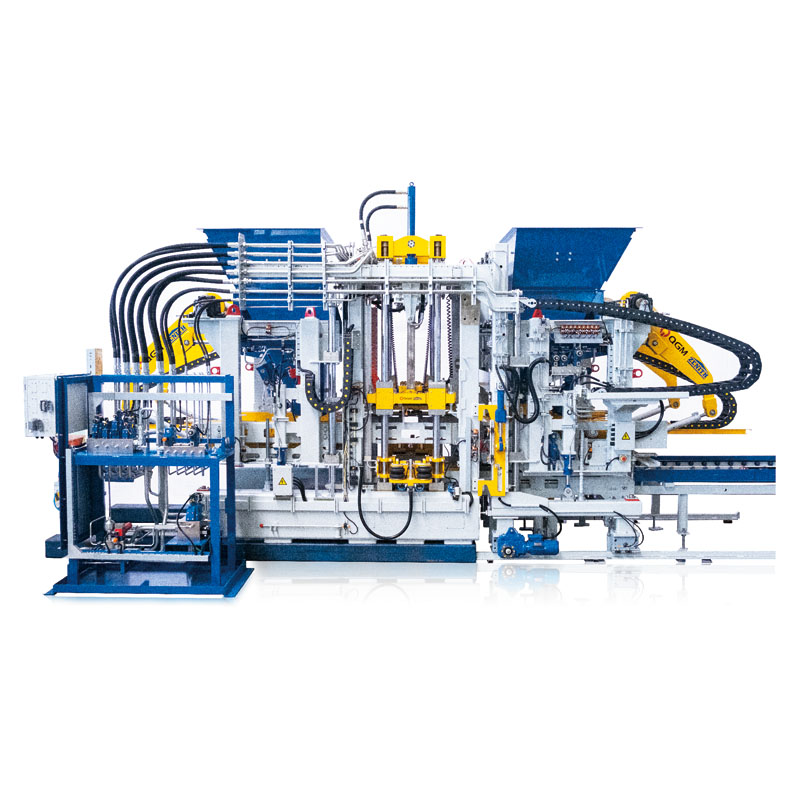

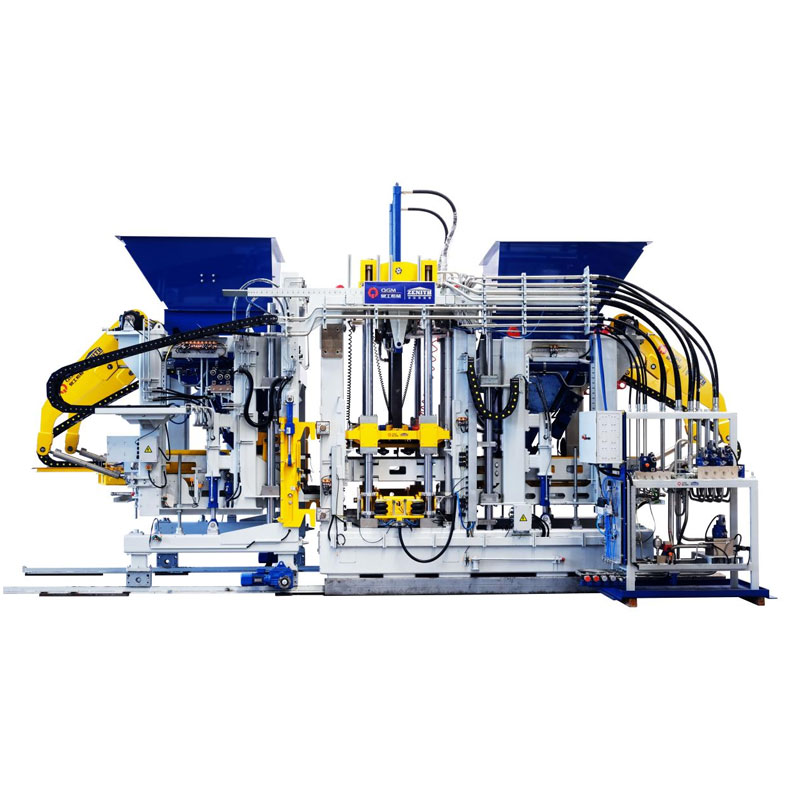

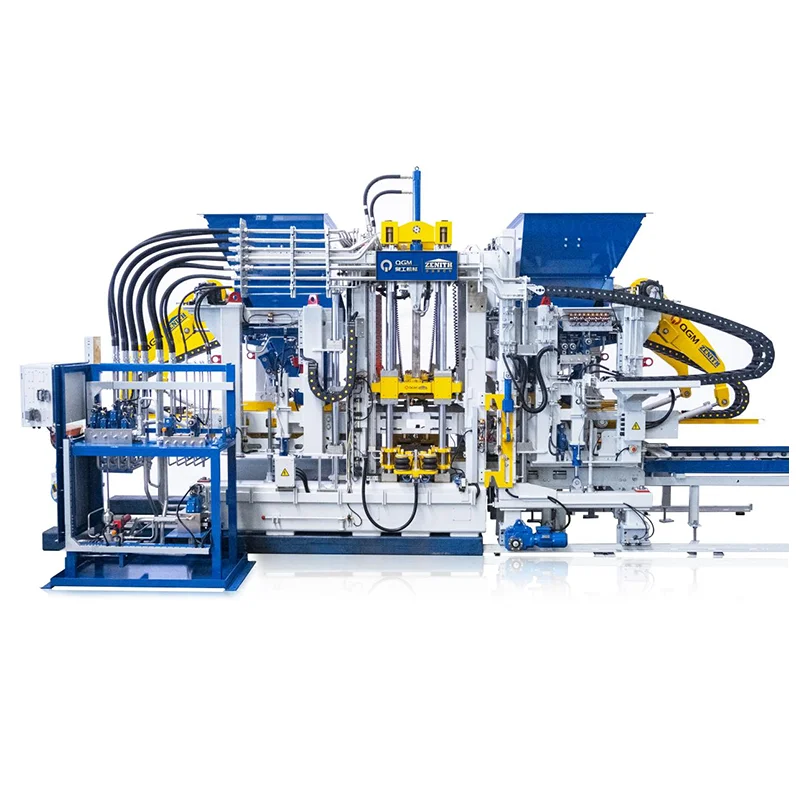

Vibration Table Design

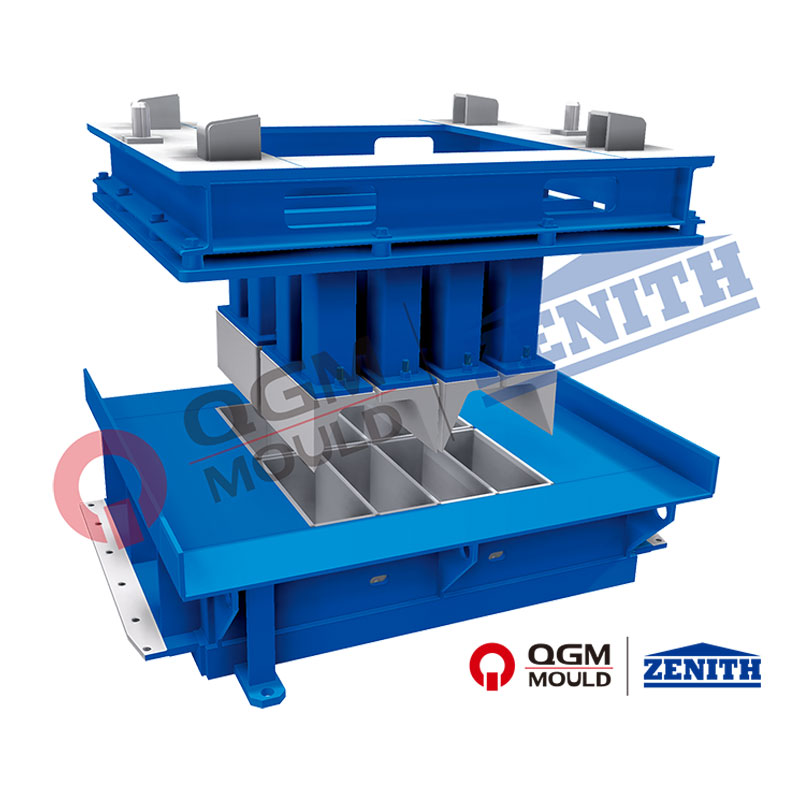

Vibration Table Design Quick Mould Changing System

Quick Mould Changing System German Version of High-quality Rack Design

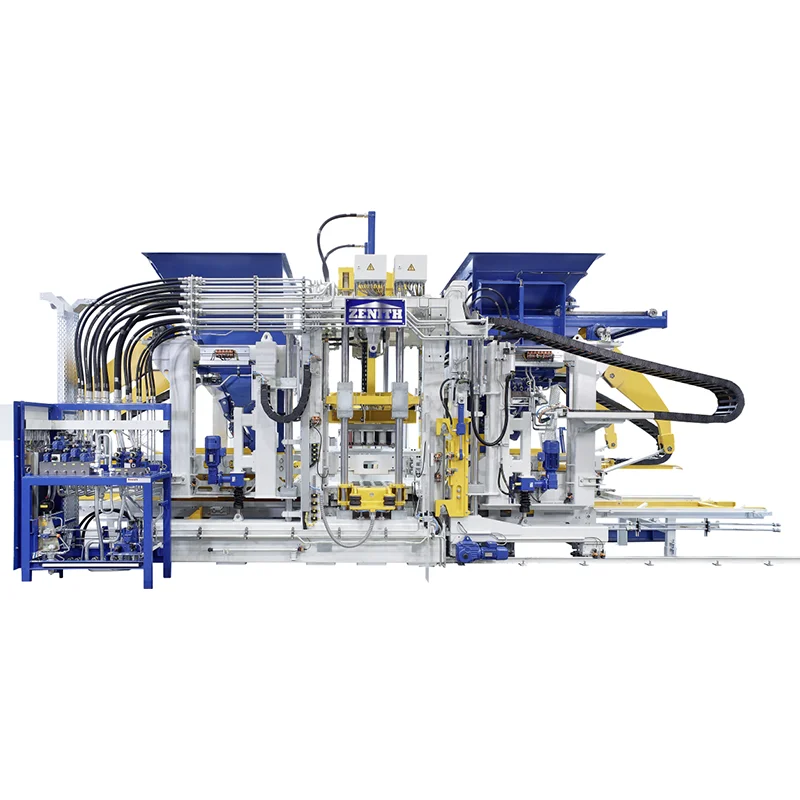

German Version of High-quality Rack Design Linear Transducer

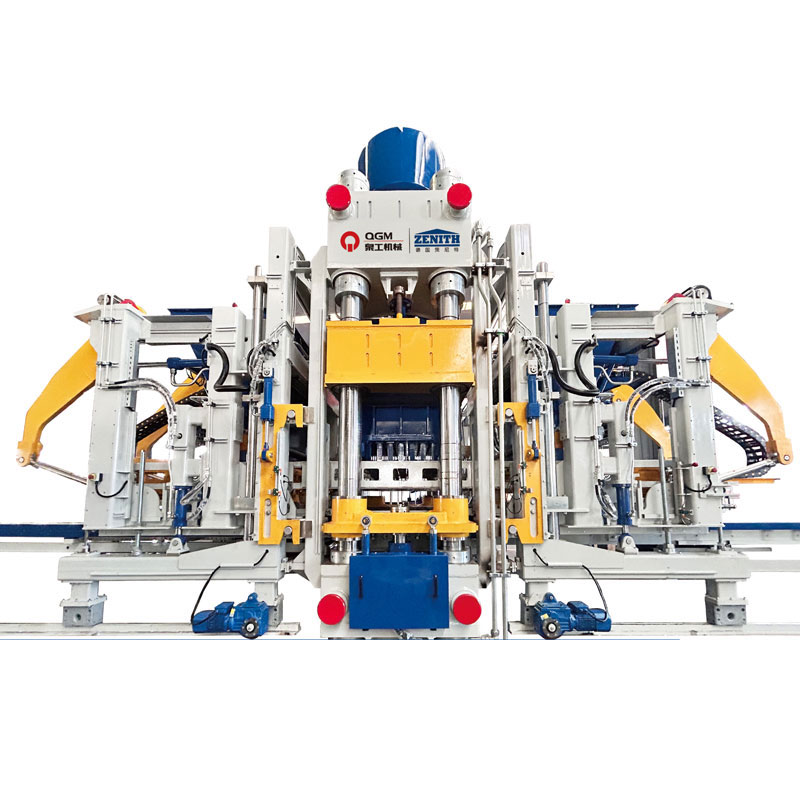

Linear Transducer Intelligent Feeding System

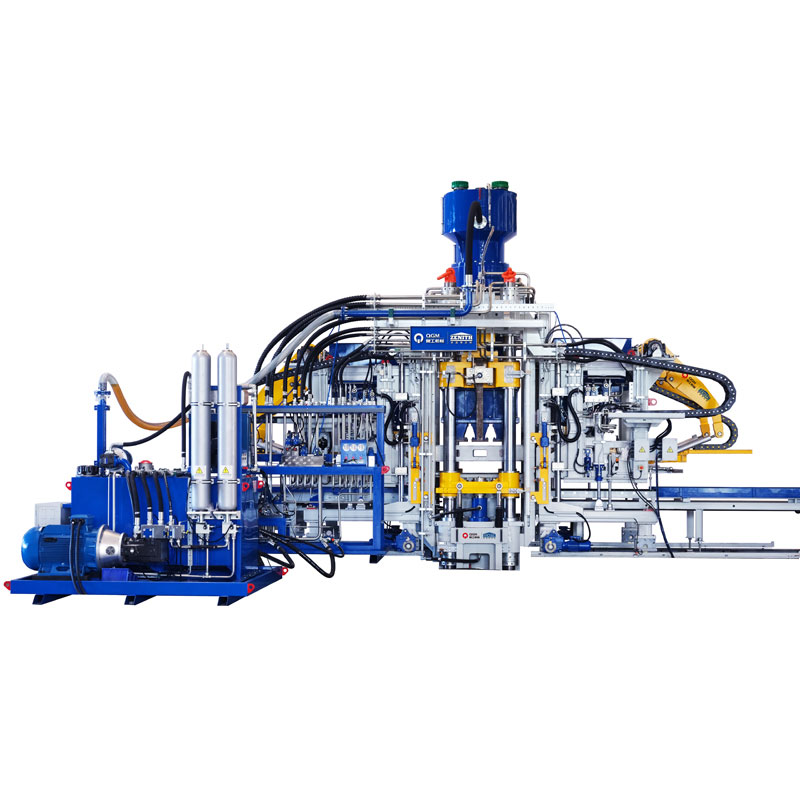

Intelligent Feeding System Precise Servo Control System

Precise Servo Control System High Precision Servo Hydraulic System

High Precision Servo Hydraulic System Leading Intelligent Cloud Service System

Leading Intelligent Cloud Service System Intelligent AR Maintenance Technology

Intelligent AR Maintenance Technology