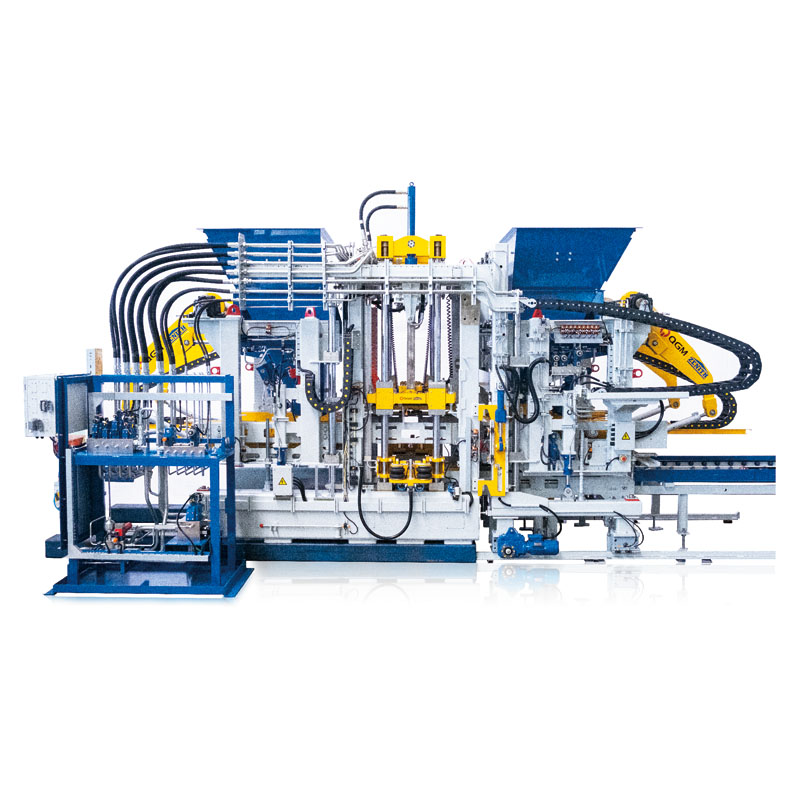

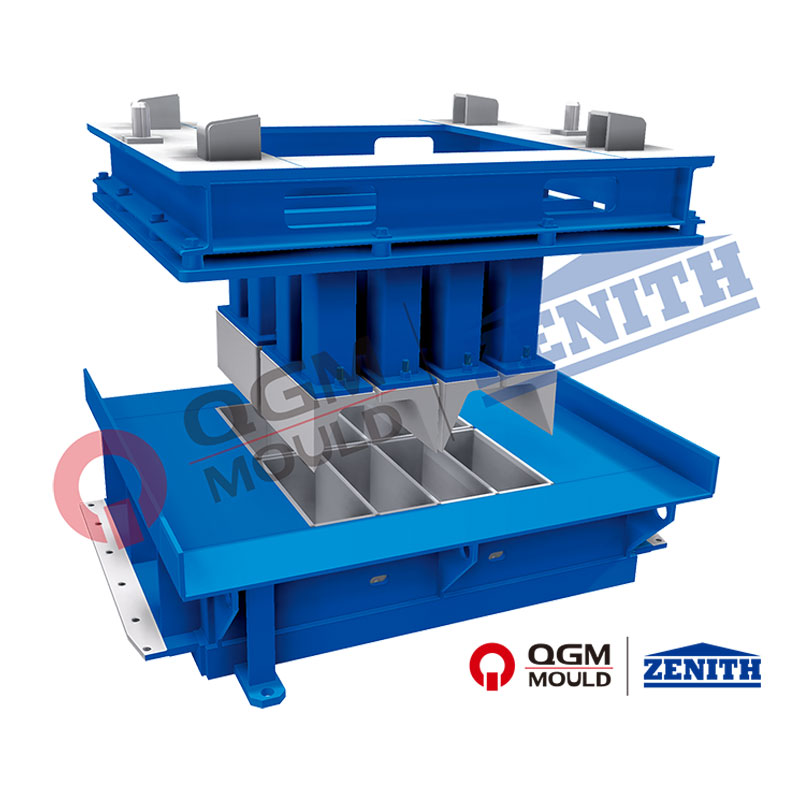

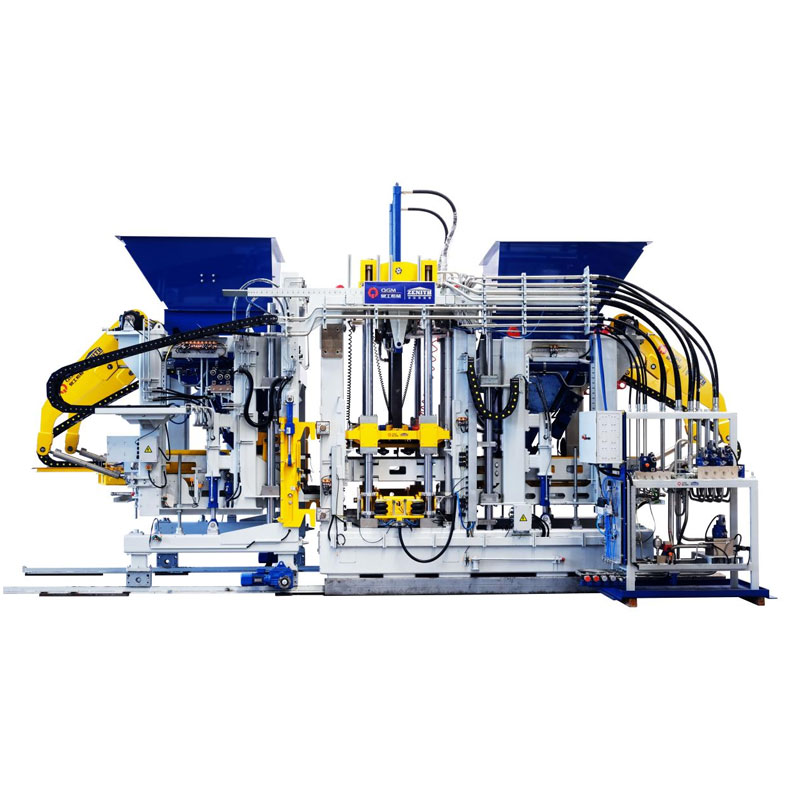

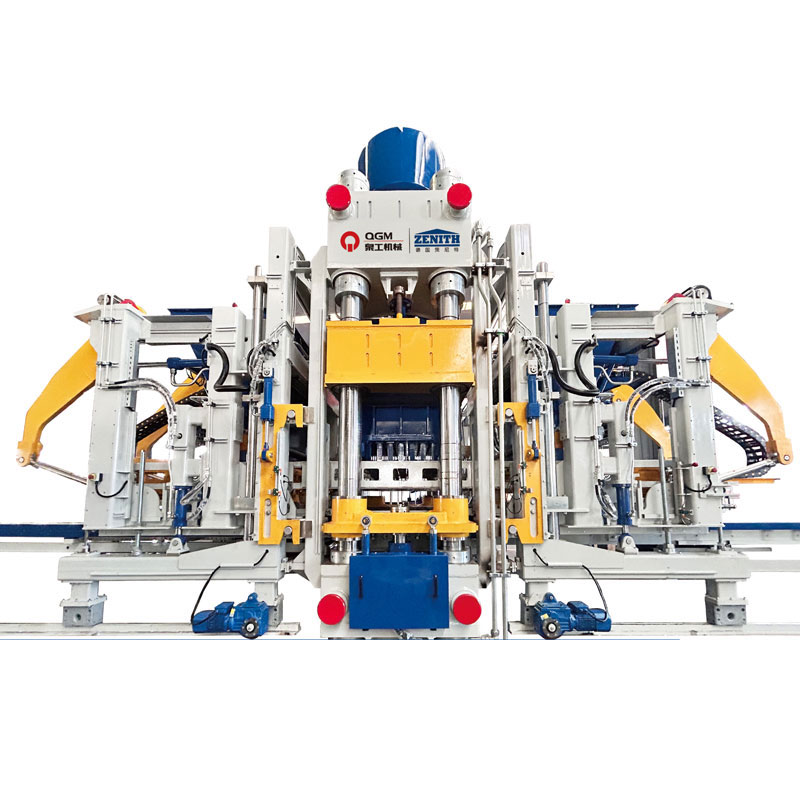

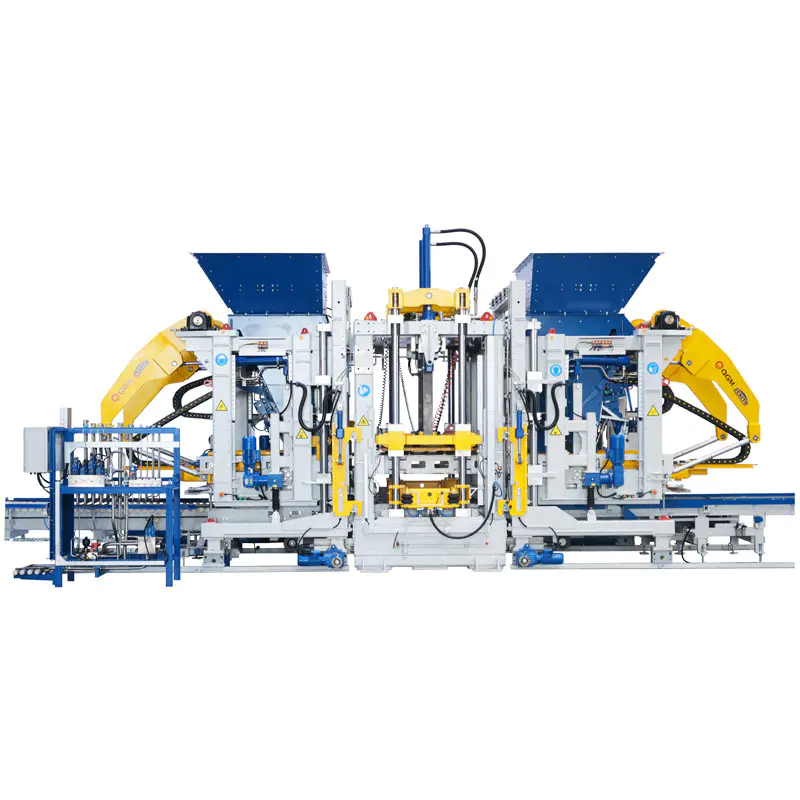

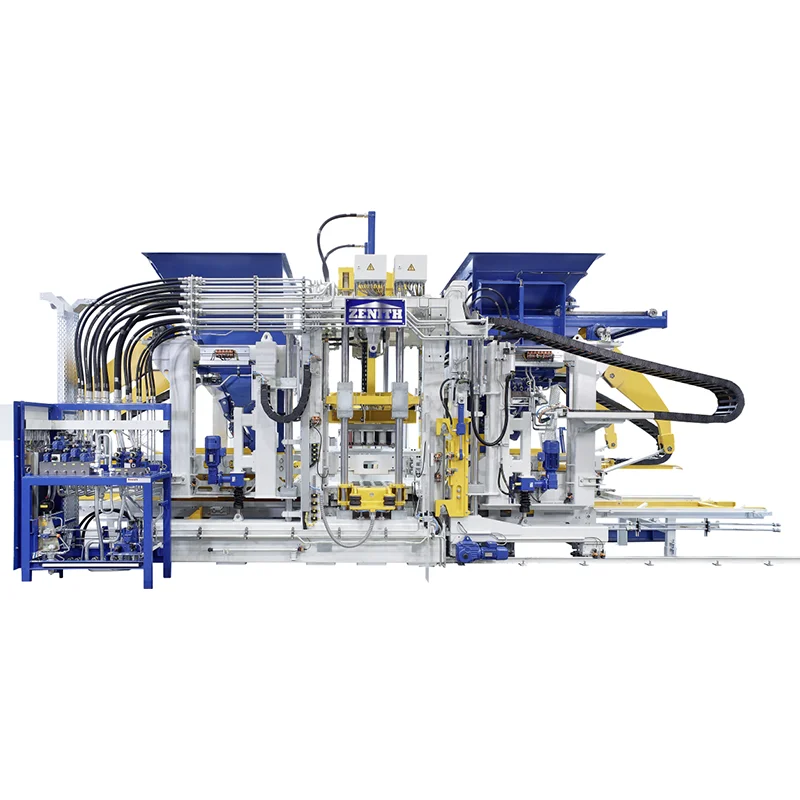

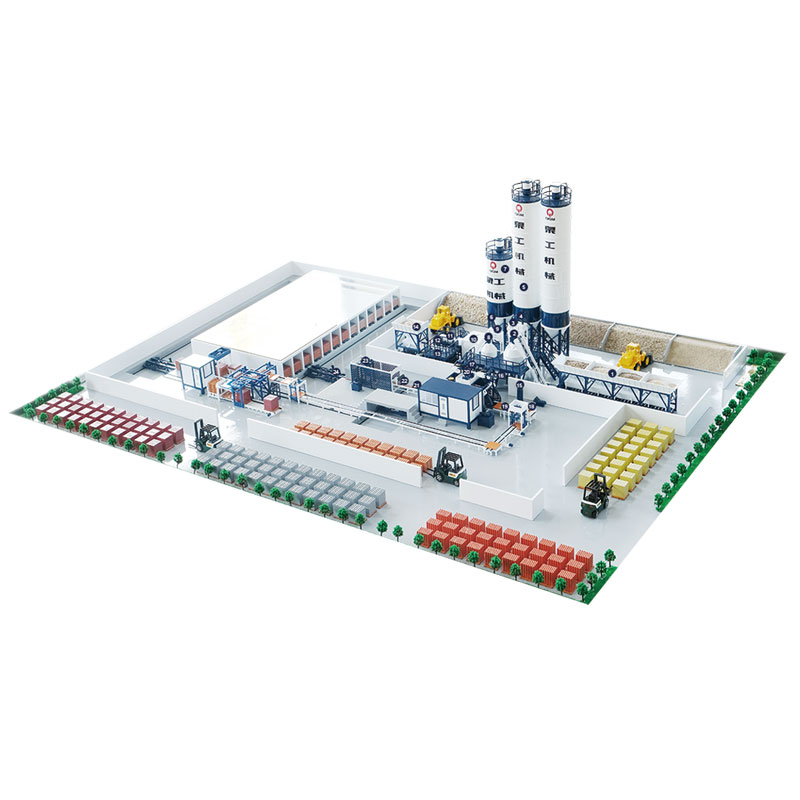

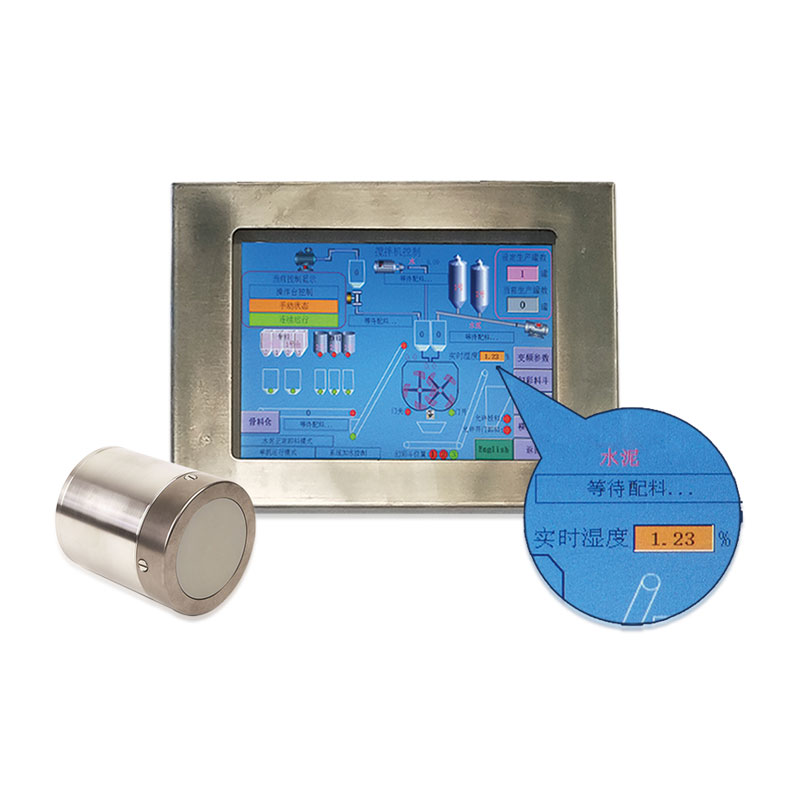

Block Making Machine Equipment is a brick-making machine used to produce various blocks (such as bricks, blocks, etc.). The products produced by the block making machine equipment can be processed into various new wall materials using industrial waste materials such as sand, stone, fly ash, coal slag, coal gangue, tailings slag, ceramsite, perlite, etc. Such as hollow cement blocks, blind hole bricks, standard bricks, etc., without sintering. Block Making Machine Equipment mostly adopts hydraulic forming mode, and some adopt vibration forming. The block making machine is silent and static pressure mode. No noise, high output, high density. No need for pallet maintenance, short maintenance cycle. Fewer people, no requirements for the working ground, and many product types. Block Making Machine Equipment is widely used in construction, roads, squares, water conservancy, gardens and other fields.